Batch management in production

Batch management is arrangement part of the full order quantity to manage machinery, manpower as per capabilities of the production and maintain quality accordingly.

Batch management is conducting for the managing the quantity of the ordered by customer to proceeding in manufacturing processes as per capacity of machinery, equipment, man power i.e. plan capacity to establishment of production processes to producing requirements materials with quality product, in the batch management is consider the major factors are time, plant capacity and product quality accordingly job order and customer specification, technical requirements. In batch management is arranging and define quantities per batch to considering quantity of job order and plant capacity, this is simple method but very important for the manufacturing & processing units to conducting / producing each job with maintain required quality in time frame.

The process of the batch management in the production is established on marketing approvals of the order from customers, when the marketing is inserted job order for the manufacturing processes that planning is conducting and establish batches, planning department is consider the job order quantity for the each batch to consider quality of the product, time frame and plan capacity to run the product in manufacturing processes, during manufacturing processes, quality department is taken the sample for the testing to ensure the product quality is as per required technical and customer specifications and requirements. Batch managing is not just bifurcation of the quantity of the job order to conduct the batch on machines or plant at different time and locations but is more about the product quality & management of the machinery and equipment should be proper busy and managing each job running in the production should complete on time.

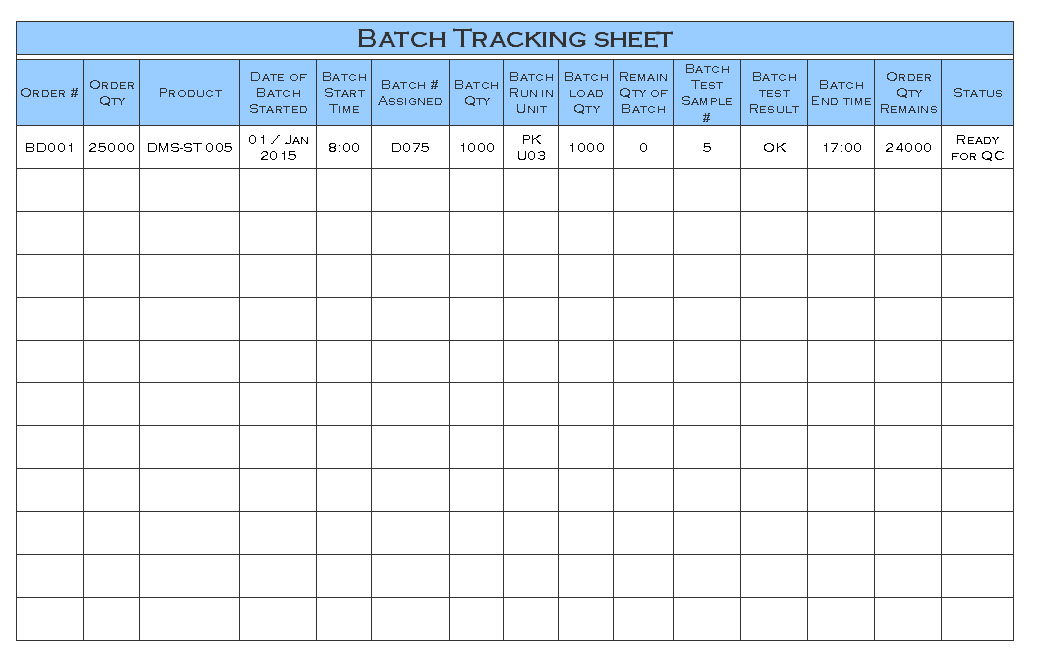

In the planning department batch wise quantity is manage that each batch should be identified with its unique number, in manufacturing processes everyone get by batch number instead the job order or customer name are not much considered for the processes, unique batch number only identity of bunch of quantity of product. On base of batch number all processes, sub processes, quality testing, in process inspection, and final quality testing is conducted to ensure each batch product quality concentration is maintained in each level of process, each batch should be same product quality is much important. Intend of provided batch number is to maintain system, organize each bunch of quantity of product and provides strong management of the resources of the plant by conducting the batch wise management. Batch numbers are helps to identify and tracking of the job order numbers and each batch are running in production, for the tracking purpose batch tracking sheet is maintained by production department to management and control of production to keep the schedules and planning by planning department. See picture below for the batch tracking sheet for reference:

As you can see picture above is example for the batch tracking in the production, each batch with date and time of start to end given the unique information and record for analysis to particular product with managed quantity, on base of the record analysis team get the information for the analysis to identify the product quality is good maintaining with quantity at running at machine, so in the next batch are manage as per analyzed information, further all the batch of job order running and when its will be finish are possible to tracking to estimate the time of production to communicate with customer for the possible delivery time and managing third party inspection, packaging and transportation concern issues or arrangement. Batch tracking sheet is very important document not only for production but all rest department to determine status of the product in production & further actions according to customer requirements. Generally this document is established and maintained by production department but the report and other analysis records manage by various departments accordingly.

Batch tracking sheet is continuous document, when any order is finished that second order is conducted in the sheet that is the same as register, but it can be manage separately order wise or establish as order wise is possible and easier for the tracking and managing material for product and planning too, batch tracking sheet is part of the batch management, batch tracking sheet’s work is finished for the job order when whole order quantity is complete and possible to move at next process, some time when the job order quantity is huge that impossible to wait for further quantity released from production to quality inspection that, batch wise quality inspection is conducted to easier for quality to move material to save the time and consider the quality of each batch which is in still production.

—————————————————————

Download Format in Word document | Excel Sheet | PDF format

Download Batch Tracking sheet

—————————————————————