Non conformance of product, process or material and control

Non conformance of product, process or materials and its analysis are conducted to reduction in non conformance by proper control & sustain procedure.

The purpose of the procedures or management of raised non conformance of the product, process or from the material which is input for the manufacturing activities or supporting to manufacturing activities that is bill of materials, raw materials and determine controls to minimize or eliminate possibilities of the non conformance in manufacturing, supporting processes of product quality, process concern or in materials. The procedures or method covers of each non conformance concern with raw materials, bill of materials, product quality due to raw material, machinery and equipment or any other ways which can be process non conformity, in process and final product. Non conformance of product or process is conducted, collecting information, analysis and controls responsibilities of production manager or general management to oversee the procedure for the maintain in routine works, in case of the raw material, consumable goods or bill of materials which is used in manufacturing process’s non conformity and concern issues are handles and responsible is procurement management to control on procurement, return, replace or control measures are defined to determine procured materials is conformed to quality product.

Non conformance of product, process or materials due to failure of characteristics to conform to customers, technical specifications, special requirements of customers that can be concern with product specifications, sizes and material properties etc, that are non conformance of product, hence non sequences, failure of systems or during the failure of product due to mismatch of the requirements of product that failure due to processes. The material which purchasing from the suppliers which is used for requirement of product or processes which active in manufacturing processes that failure are considered as material failures or non conforming materials. All the non conformance materials are returned to supplier for conformity or replacement, repair etc, hence the product non conformance are conducted for re-works, re-process or for disposal in case a non conformance or in process problem that can not be repaired. Disposed product is usually permanently destroyed from the manufacturing areas or workplace or moved to disposal areas. In case of the process non conformance are conducted, identified and controls in the processes for eliminate of non conformance.

There are some steps are conducted in case of the product, process and materials are non conformance are identified that managing by below ways for further processes & same ways controls are deployed for the attend non conformance of product, process or materials which is raised from customers, suppliers or internally. See below actions that are conducted with the product, processes or materials to managing or controlling with non conformance are occurred:

- Disposal – in case of the product identified as non conforming with specifications, characteristics to customer requirements and problems is not possible to removed or not turned in conformance that product is not usable for regular processes are considers and destroyed as disposal actions at workplaces and removed from it or move at disposal areas.

- Reworks – The product identified as none conforming that a process that performed on product non conformance to completely removed problems by rework processes to meet the customer technical specifications and requirements of end applications.

- Return – The materials are procured for the manufacturing activities, supporting processes as bill of material or consumable goods that directly effect the product quality which having identified non conforming that is required to be returned to the supplier for the further actions that is rework or replace the materials against procurement.

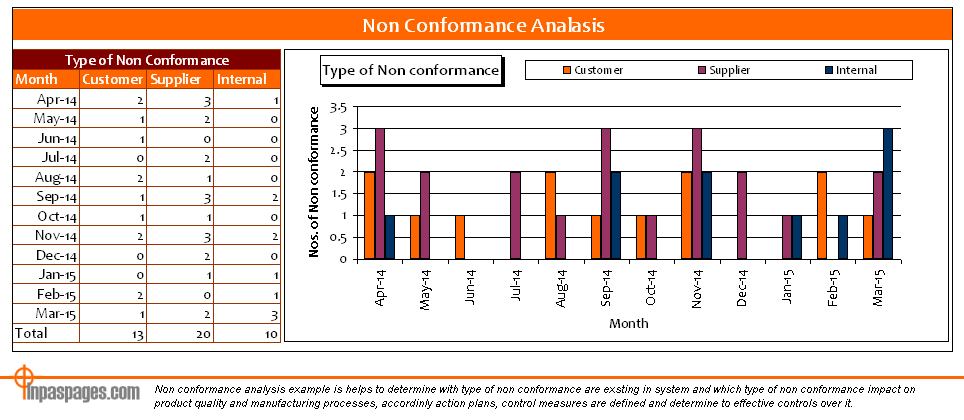

In case the customer decided to use a non conformed product or materials with further processes (if the customer’s end applications are non impact of non conformance of products in that cases) to get the final product on timely which has be determined to use for production with its existing condition, the materials / product should approved by customers or internal management to impacts on the end application of customer will not effective on product quality. with slight deviation / variation with the product in tolerances from the set characteristics of product are accept by customers that should considered the product tolerances / characteristics non conformance by approved by customers. See below picture for reference for identified type of conformance in system:

As you can see picture above helps to identification of the monthly non conformance identified during processes, producing materials for the customers, there are three types of non conformance are identified as below:

- Customer – this non conformance raised by customers after the product are sold, the product delivered and after in process at customer end non conformance identified that non conformance are managing in customer category.

- Supplier – Material procured from the supplier for internal manufacturing processes and supporting processes that directly or indirectly effects on product quality or the materials procured is identified against required specifications, those materials are considered as non conformance and managing in supplier category.

- Internal – When the material is identified as non confirming in in-process activities during the in process inspections, sampling process or any other ways that can material non conformance, process non conformance or product non conformance which are due to inspection of internal audits are conducted and identified that it will be managing as internal non conformance.

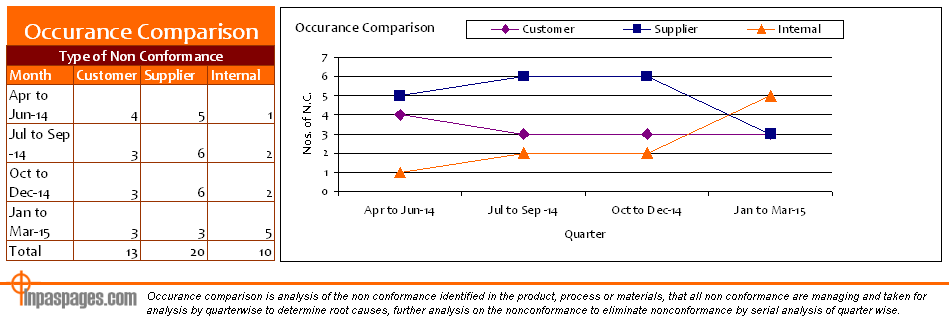

On based of above analysis, team can identified root causes of non conformance appropriate reasons of failure in process, procurement and raw materials before or in process activities, root cause and find out source of non conformance are conducted base on above analysis that in which condition in which month and what was the reasons of the condition of non conformance is identified that possible to tracking the system for managing proper action to corrective and preventive actions for minimize non conformance in system. Same here as below see picture that indicate the quarter analysis of the non conformance identified in appropriate months, see picture below of occurrence comparison of non conformance:

Analysis of non conformance in processes of product or materials are conducted as quarter wise analysis to determine occurrence comparison through which type of non conformance and which quarter with by which category having the most frequent or numbers of non conformance are identified during the quarters, on base of the occurrence of non conformity, team can analysis and identify root cause of particular quarter which is higher among all the quarters to determine decision on source of non conformance and required controls to minimize or reduce non conformity in processes.

All non conforming product or materials should properly identified and segregated to ensure all non conforming product / materials does not mixed with conforming product / materials, all the non conforming product should be proper tagged, labeled and immediate transfer to storage / disposal of non conforming product. If the product is identify after supply to customer that all the required reviews are conducted and determine root cause of the problems to reach to source of non conformity. The detailed information should conduct with all analysis and record to improvement of system.

——————————————————————–

Download format in Word Document | Excel Sheet | PDF Format

Download non conformance analysis

——————————————————————–