Measuring Monitoring and Analysis – Product Realization

Measurement and monitoring activities are conducted to ensure and verify product conformity to considered technical specifications and product characteristics.

The process describe the guideline of monitoring and measuring of product and product realization processes, measurement and monitoring activities are conducted for the product quality conformity, technical and specifications of product are verify and ensure the product is produced as per standard requirements. Product realization need to measure and monitor activities on verification of purchased product, in-process inspection and quality final inspection and also on the packaging material, equipment and tooling calibration and standards.

According to planning of product realization processes, management is determining identification, appropriate measurements and monitoring of product and product realization process. The product quality is confirmed to implement quality system and system audit is assurance of quality conformity and effectiveness of the system to comply the requirement of standard for maintain quality product for customer satisfaction. All the records, documents of the concern process and activities are reviewed by management and are used to assurance of quality improvement.

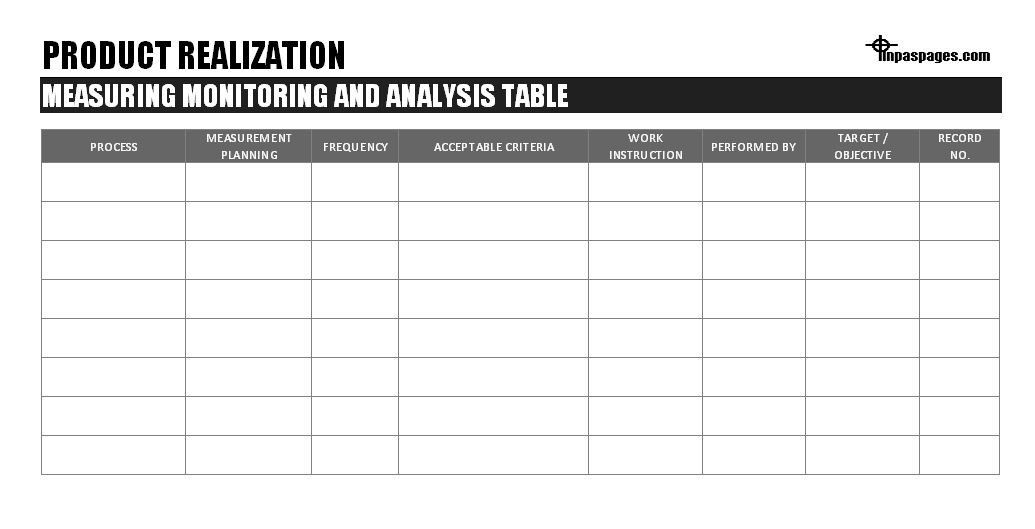

Company should maintain proper documented procedure and records for the each activities of measuring, monitoring and analysis for product realization process, generally management is prepared the simple table that conducting all activities concern the measuring, monitoring and analysis detailed information, record in simple table, if the company implemented design and development and applicable clause of standards that should documented procedures should established. Product realization measuring, monitoring and analysis are maintained in table is called “measuring monitoring and analysis table” see picture below:

Measuring, monitoring and analysis table is recorded information for the planning measurement that helps to performance of task, frequency of the measurements, in process or on final stage who will be perform task or who had done the measurement task are also covered. For the measurement, monitoring and analysis is perform as per work instructions, product standards and technical specification and requirements of customer, and same record information are maintain in the table.

Measurement, monitoring and analysis are conducted by some techniques that help to ensure the product quality and measurements are match with required product quality and specifications. There are various processes helps to measuring, monitoring and analysis, Sampling Plan, Statistical techniques etc, are generally used for the measuring, monitoring and analysis of product quality. in the statistical techniques are used for the testing and validation of process which is part of the analysis, evaluation of measurements and quality performance. Hence sampling plan for individual product part that is sample testing and inspecting, analysis upon requirements and process acceptances activities are covered and documented.

Conclusion

- Planning and implement measurement, monitoring and analysis and improvement process to ensure conformity of the quality management system and continual improvement by effective process to ensure quality product

- Establishment of documented procedures, records for criteria, frequency and method of monitoring and analysis to ensure quality objectives.

- Planning for actions to eliminate defects and nonconformities, causes of defects by verification and results analysis.

- Collecting information, data for analysis for result of analysis on the performance of the internal management system to concern product conformity, customer satisfaction and product characteristics and trend of manufacturing process.

———————————————————-

Download Format in word Document | Excel Sheet | PDF Format

Download measuring monitoring and analysis table

———————————————————–