What is manufacturing process?

Manufacturing process is sequence of specific operation which prepare by product realization. Manufacturing process is sequences and interaction of the particular operation for particular product producing. Manufacturing process through possible to transform raw material in to finish product. Manufacturing process is developed for providing structural or mapped procedure to easy & reliable sequences.

Manufacturing process that part of the production activities which is related with product form and material type that the material being produce. In the Manufacturing process doesn’t include other activities like storage, transportation, dispatch etc…

Manufacturing process only related to those activities which by finish product are developed from raw material with other supporting material.

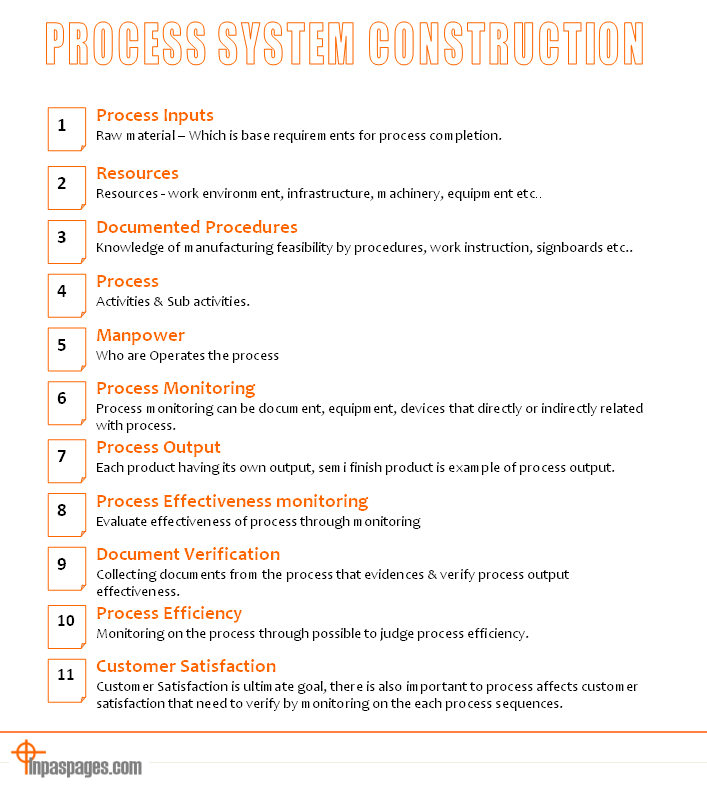

Process System Construction

- Process Input (Consumed for this Process completion) is the input of the process like we enter the raw material in the process for the producing material, this is first step that indicting input material for the start process by consume raw material to completion process.

- Utilities & Accessories (Resources) – Requirements for the producing material, in the manufacturing process requirements should be fulfill by some basic requirements that is resources, work environment, infrastructure, machinery, equipment etc.. By help of the resources can possible to go ahead step of manufacturing process.

- Documented Procedure (Information is must for this process completion)– Flow of the information are depends on the product realization, each information are collecting and manage as documents, sequences of the process, work requirements & rhythm of the process is documented as work instruction, procedures and other concern documents which helps to maintain product quality & uniformity.

- Process (What is the Process) – Process is the activities or sub activities through manufacturing sequences & interactions are conduct. The activities are depends on the product and realization.

- Operates the process (Manpower) – Manpower is pivot part of the manufacturing activities; all the required operations are conduct by manpower.

- Process Monitoring & Process Monitoring Parameters – Process monitoring and monitoring parameter is base requirements that making the product as required by customer to support of the devices, equipment that directly or indirectly attached with process.

- Process Output – Each process having its own output, there is important that during the process mapping, developer know the fact output from the process, this will be depend on the product and its output but the output is semi finish product that output converted in finish product.

- Evaluate Process effectiveness – There are several ways to conducting evaluation of process effectiveness, when we take any process in hand that output are the evidence of the process is effectively conducted or not. Evaluation of the process effectiveness is audited by process effectiveness monitoring. Some examples are as below:

- When the manufacturer is deliver the material on timely that evidence of the process is conducted effectively

- The documents is evidence of the process, on base of the process analysis are possible to collect the information like a product rejection, customer complaints etc..

- Documents to verify process output effectiveness – Documents are evidence of the process and its activities that need to prepared and maintain accurately, each process input to output are conducted and recorded in document those documents should be verify process output effectiveness.

- Evaluate process efficiency – This is also important that each process should not be time consuming and efficient for the process owner, but how to evaluate that is efficient, here some ways for judge it.

- For maintenance department – if the process is efficient that monthly cost trend should be positive that indicate the strong process efficiency.

- In production Department – Machine are used natural resources that trend of consumption by judge the process is efficient or not. Machine manufacturers are providing the documents of the natural resource standard use that helps to understand trend of the consumption.

- Documents of the process effectiveness – machine consumption trends, overall equipment efficiency, complaint records etc.. Helps to understand documents to verify process output efficiency.

- Customer satisfaction (How Affect Customer Satisfaction) – If the product realization is not reviewed properly, production, quality assurance & controlling will not get adequate inputs to meet customer requirements, in that cases customer satisfaction can affects. Manufacturing process is pivot for the customer satisfaction that each sequences & interactions are base of the customer’s technical & level of satisfaction

You would also like to read: