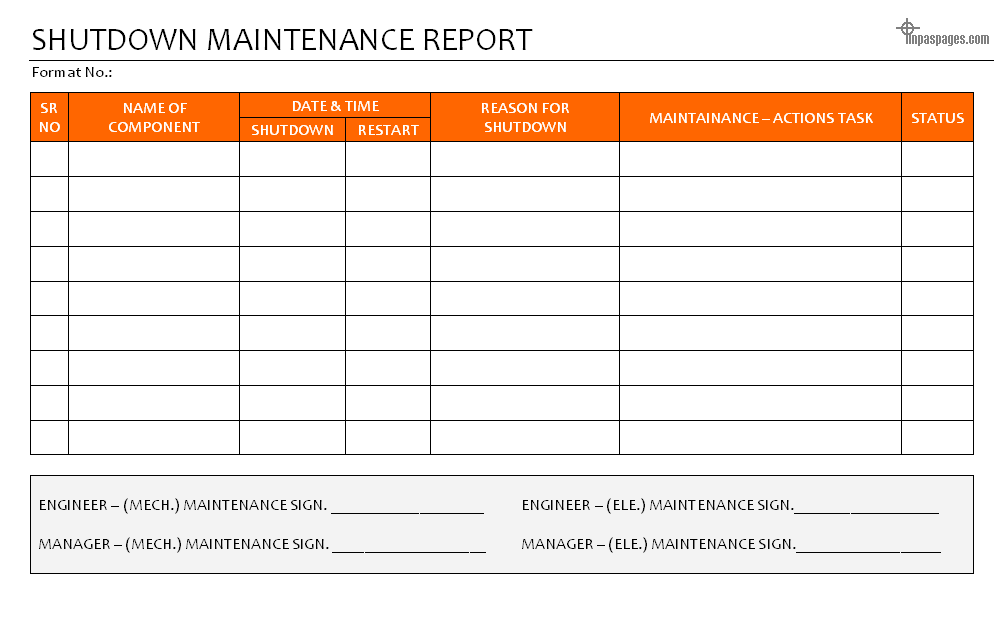

Shutdown maintenance report

When any machine, equipment are under maintenance meanwhile machine activities, production are stopped completely this time called shutdown maintenance, during the time period only machine / equipment maintenance activities are conduct to repair / service machinery / equipment and completely stop further activities hence this maintenance activities is reducing productivity, time & increase costing of the product manufacturing hence its very important to calculate each machine / equipment shutdown maintenance time and calculate each minutes against production loss bear by company to identify reasons behind shutdown, machinery routine errors and other opposite factor that reducing production.

Why required reporting for shutdown maintenance?

Time – Active management always focus on the time factor, to calculate time of total available hours & remain time to manage for enhance maximum production is very important for management & management should need to controlling on the waste of the time during working time by awareness or workmen or any other motivation ways.

Overall equipment efficiency – Shutdown maintenance is decreasing overall equipment efficiency that company directly loss reason that production is drastically down, when overall equipment efficiency percentage down, management need to focus on data or report of the effective factor and shutdown maintenance report is one of the most which effect on overall equipment efficiency.

Costing – when the finance calculate the product costing that machine downtime is consider as losses of the time & money because its became multiple when any machine goes in maintenance, time of machine, humans, equipment and supporting departments are free from the activities hence its loss for management and its direct effects to consider money bear by cost of product.

Preventive Maintenance or Cleaning lubrication inspection tightening – on base of the shutdown maintenance report, other regular task like preventive maintenance and cleaning lubrication inspection tightening which is effectively not performed hence during the Preventive maintenance activities defective parts are not proper identified which is not good deal for the maintenance and management too, preventive maintenance and cleaning lubrication inspection tightening are conduct for identification of weak part of the machine / equipment hence this report helps to increase in performance of the both activities in company to reduce time of shutdown of machinery / equipment.

Human productivity & interest – when any machinery / equipment goes in maintenance working peoples productivity are decrease due to daily activities are break along with machine and human rhythm, peoples are much unoccupied meanwhile hence its interest in the work are decrease, as I personally experience that any machine are goes against and again in maintenance, operator are always complaint for machine change, in case of not that oblivion level is increase in operators, hence management must has to consider it.

Product delivery & Schedules – product delivery and schedule is bear due to shutdown maintenance is state view, hence if the management have proper reporting of the shutdown maintenance information that to reach at the timely delivery, product wise management can arrangement and schedules are possible to change to maintain customer satisfaction.

Product Quality – when the machine is not proper perform or shutdown maintenance are increase nos of time that product quality is effect due to time factor, management try for the reschedule or arrangement on the other machine that set for the other product or size as result its directly effect on product quality.

Machine / Equipment Self life – on base of the shutdown maintenance reporting, management can get the idea of the machine self life, if the nos. of shutdown is increase in ratio that need to proper action to terminate machine or part change or focus on proper preventive maintenance, hence its supporting MIS.

To consider above all the things are very important for the company that without machine production is not possible and without proper maintenance machine can’t perform better, hence shutdown maintenance report helps through many ways.

EXAMPLES, SAMPLES & FORMATS

SHUTDOWN MAINTENANCE REPORT IN WORD DOCUMENT DOWNLOAD FREE

SHUTDOWN MAINTENANCE REPORT IN PDF FORMAT DOWNLOAD FREE

SHUTDOWN MAINTENANCE REPORT TEMPLATES DOWNLOAD

SHUTDOWN MAINTENANCE REPORT IN JPEG, PNG FORMAT DOWNLOAD