Product Recovery Report

In manufacturing industry, product rejections, and defects of the products is very common but very serious subject that need to minimize level of the rejects due to some defects. In the product manufacturing company is always try to eliminate possibility of the rejection by take some actions on the raw material to finish material processes, and its necessary to controlling on each process to minimize rejections.

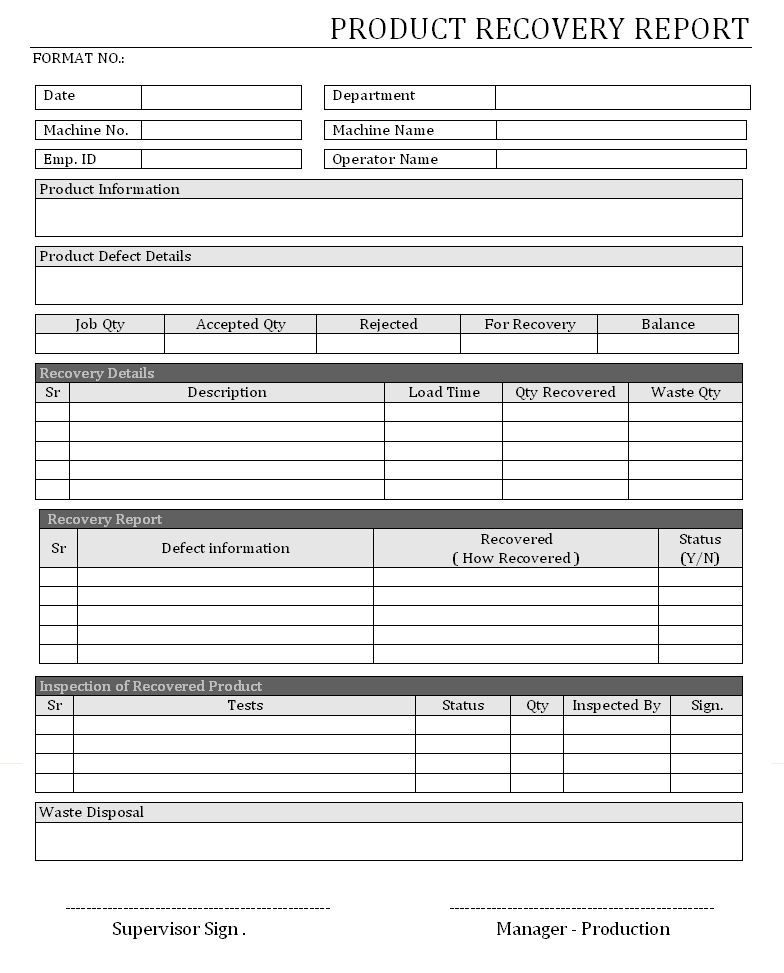

For the controlling on the rejection need to continuous monitoring on tracks of the each step of the production process. In case of any rejection, defects are found during the manufacturing process that try to recover the product to minimize costing of the processes and product. Here as below given example for the product recovery report which is generate by the try of the recovery process:

Date of product recovery report

In which department this product recovery is being in process, generally before the product recovery, analyze that which kind of defects having with product on base of the recovery process is possible.

Machinery Number and Machine name where on product recovery process is established.

Employee Identification of the machine operator who is taken the process common over machine.

Product Information – Full detail of the product to easier for the recovery process

For the recovery process – Required total information like Total Job quantity, Accepted quantity, rejected quantity and taken for recovery quantity and after balance of the job quantity remains.

Recovery Details – In the recovery details mostly full description of the recovery process, information of the process, total load time, quantity recovered during the process and how much waste generated from, all the information needed.

Recovery report – is the reason and cause type information where what was the defects on before the recover and how the recovery where possible that information of the recovery is very important for the next future with status of current possible.

All the recovered product inspection is also very important that there all the required and done testing process, status of the inspection process, total quantity taken for the inspection, inspector name and signature to ensure all the recovered product is tested.

Waste disposal is also very important part of the product concern that during the whole process how much and waste was handled during and after the process.

EXAMPLES, SAMPLES & FORMATS

PRODUCT RECOVERY REPORT IN WORD DOCUMENT DOWNLOAD FREE

PRODUCT RECOVERY REPORT IN PDF FORMAT DOWNLOAD FREE

PRODUCT RECOVERY REPORT TEMPLATES DOWNLOAD

PRODUCT RECOVERY REPORT IN JPEG, PNG FORMAT DOWNLOAD

You would also like to read:

FINISHED PRODUCT STORAGE CHECKLIST

PRODUCT DEVELOPMENT PLANNING CHART

HYGIENE PERFORMANCE CHECKLIST FOR FOOD PRODUCT